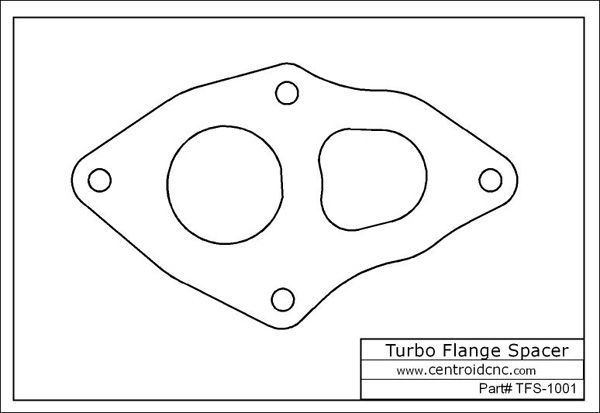

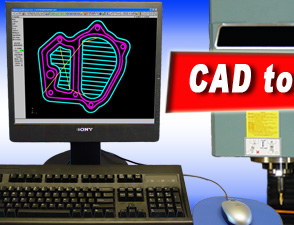

CAD to CNC, DXF Import turns your CAD files into CNC part programs .

Machine parts from a CAD DXF file with CENTROID’s DXF Import.

-Imports DXF files directly into conversational

-Fast results, easy to learn.

-Easily combine with conversational events!

-Graphical interface, you choose what to machine.

-Pocketing, Contouring, Drilling, Tapping

-Engraving, Logos, Art

-Import DXF with USB, USB Floppy or LAN

-Use Mouse of Keys to select features

-Use right on the control and/or on a PC

-No CAD/CAM system necessary

-Easier to learn than a CAD/CAM system

-Less expensive than a CAD/CAM system

-Intuitive for conversational users to learn.

Step #1

Import DXF file into the control with the supplied USB port, the Floppy Disk or the ethernet LAN connection.

In addition to creating part programs for a CAD file right at the control, CENTROID’s Intercon Conversational with DXF import is also available for your Desktop PC. With the offline version you will be able to create part programs for your CENTROID CNC control in the comfort of your office.

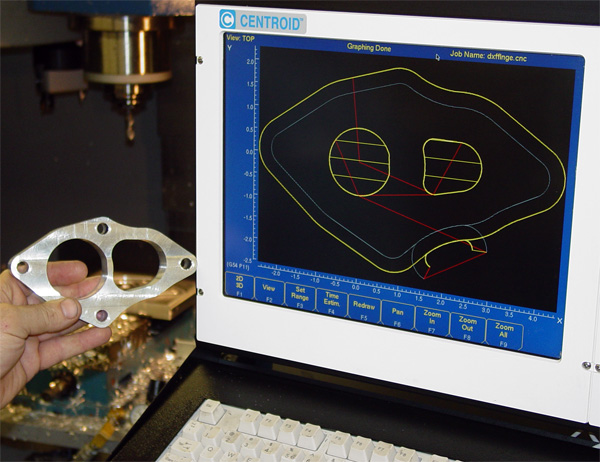

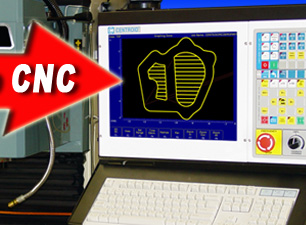

Step #2

Using the mouse and the keyboard select the parts of the CAD file you want to machine, select the type of machining to be done, change the part zero point, add in cuter comp (if necessary) and the tool path is created automatically.

View graphics of your work at any time, easily go back and make changes to any part of your work. Graphics show both porgrammed path the the cutter compensated path.

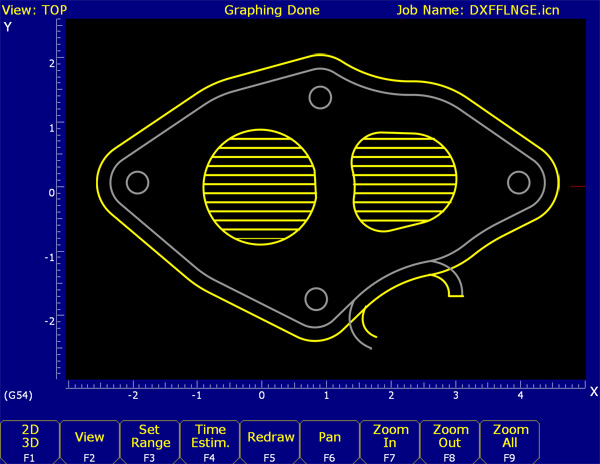

Step #3

Set up your vise or fixture and machine the part.

With a CENTROID CNC control you can stop the job at any point for any reason and resume right where you left off. The control automatically keeps track of where it was machining when stopped and will start right back up at the begining of that line or arc OR where ever you want.

Here you see the final finish pass on our Turbo Flange adapter, we had Intercon automatically create several passes of the outside contour to reach the final depth, then the finish pass is made at full depth for the best possible surface finish.

Works with any CAD/CAM system that posts G&M codes.

With a CENTROID CNC Control you can create tool path with any CAD/CAM system on your desktop PC. You can transfer the toolpath into the control via any USB device and/or the Ethernet Lan connection. Your CAD/CAM generated Tool paths will be stored on the CENTROID built in Hard drive so you don’t have to reload any programs once there in the control. You can view the CAD/CAM generated tool path on the CENTROID in 2D and 3D views, you can also see and edit the CAD/CAM generated G code right at the control so no need to go back to your desktop PC for simple changes.

Here are just a few of the popular CAD/CAM systems that our customers use. | ||||||||||